Boston T Yoyos

Design and manufacturing project: Fabricating 50 yoyos.

With a team of 6 students we designed a yoyo from scratch, produced tooling, and manufactured a batch of 50 exemplars.

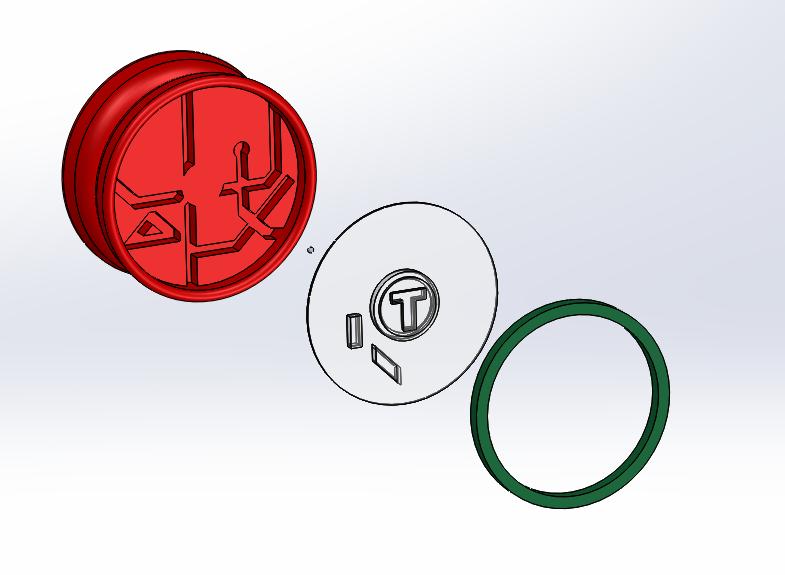

Each yoyo half consists of an injection molded body with an extruded maze design, a transparent thermoform part and an injection molded ring that snap fits into the body and holds the thermoform in place. The maze resembles the Boston subway system in which a small ball can roll around. The thermoformed part has recesses which allow the ball to change lines, there is also a central hub with the ‘T’ logo. The two halfes have hex nuts embedded into their backs, such that they can be joined by a threaded shaft.

The injection molding and thermoform molds were machined on a CNC lathe and a CNC mill. We created and optimized the toolpaths based on the CAD mold models.

I was especially involved in the CAD design of the parts and their molds, as well as the machining of the latter. We created a blog during the course of the project which documents our progress in some greater detail. This class introduced me to modern CAM tools and I learned how to better design for manufacturing. I also acquired more knowledge about modern manufacturing methods (in particular additive manufacturing) and was introducing to project management tools.